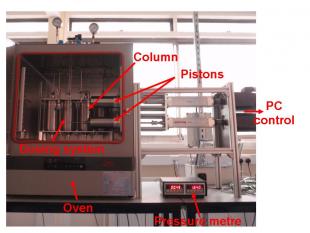

The Dual Piston-Pressure Swing Adsorption (DP-PSA) apparatus is a unique, custom-built system for testing novel adsorbent materials for the separation of CO2 from flue gas.

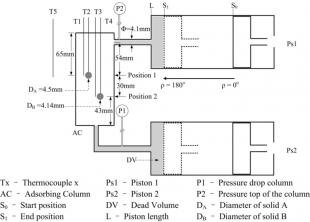

Two pistons moving in cylinders at each end of the adsorption column induce the cycling of fluid flows and pressure variations in the fixed bed. The system can be run at both pre-combustion and post-combustion capture conditions and with a wide range of cycle times (minutes to less than one second) thus covering most of the operating conditions encountered in Carbon Capture processes. The system is connected to the National Instruments Compact Rio that provides advanced signal processing, data analysis and control capability as well as automated running of series of experiments.

Benefits of the DP-PSA system

- Direct test for the separation performance

- Single column with a modest amount of adsorbent (<15g)

- Closed system with total reflux: only a small amount of gas needed

- Rapid testing of adsorbent materials

- Model system for large-scale processes

- Many different experiments are possible

- Particularly suited to measure kinetic properties at fast cycle times

Variable operating conditions

- Different piston configurations: stroke lenghts, phase angle and cycle shapes

- Fast cycles times up to 2 Hz

- Different starting pressures: 0.1 to 20 bar

- Different initial temperatures: 20 °C to 200 °C

Measurements

- Absolute pressure and pressure drop along the column

- Two pairs of thermocouples along the column

- In each pair one in the gas phase and one inside the adsorbent pellet

- One thermocouple in the oven

Related publications:

- Friedrich, Ferrari and Brandani: Efficient simulation and acceleration of convergence for a Dual Piston Pressure Swing Adsorption (DP-PSA) system. Ind. Eng. Chem. Res., 2013, 52 (26), pp 8897–8905.

- Wang, Friedrich, Brandani: Characterisation of an automated Dual Piston Pressure Swing Adsorption (DP-PSA) system. Energy Procedia, in press.